Technology Project: Powder Dispenser

Monday, October 8, 2012

Monday, September 10, 2012

Prototype (Upgraded)

- We had some problems with the previous prototype, and we upgraded them by solving the problems.

- The first problem was the type of tube. The colour of the tube we have used for the previous prototype was white. We have purchased the one that is clear so the powders can be seen through the tube.

- The next problem was that the number of tubes we had to produce. For three different amounts of powders for three consistencies, we had to make three different sizes of the tubes. However, we thought that it would be much better to make just one tube that can be used for the all three of the consistencies. Therefore, we have made the wooden tool much longer.

- Also, we thought about putting the rubber around the tube so the height of the tool can be adjusted inside the tube. We found the useful material which is called "O" ring. By doing so, the amount of powders we can get from the tube becomes more accurate

- The photos below show the steps we have done when producing our device. The sketch was drawn with dimensions in full scale, and it was used when we made our product.

Wednesday, September 5, 2012

- We are thinking of putting a scale sticker on the clear tubes. The scale sticker will show the numbers in centimetres. The numbers such as 3, 5 and 11 (cm) will indicate that the amount of powders required for the specific consistency, Ketchup, Mayonnaise and Peanut Butter. The transparent scale allows easy measurement of the volume.

- The inside diameter of the clear PVC tube is 3.4 cm.

- We use the numbers from the table (previous post), and then we have calculated the volume of the powders we need for each consistency. This volume will be used when defining the heights.

- http://image.made-in-china.com/4f0j00VehaBvEMZPks/100ml-Syringe-Luer-Lock.jpg

Learning Outcome 5

Explain any implications of Te Tiriti i Waitangi

- How do we demonstrate our understanding of the 'implications of the Treaty of Waitangi' in our technology project?

- What were initial expectations in our process regarding the implications of the Treaty of our technology project?

- What supports, challenges and dilemmas were encountered as we attempt to fulfil the technology problems towards the Treaty within our technology project?

Tuesday, September 4, 2012

Plastic Systems

We have been to Plastic Systems to purchase clear PVC tubes. We bought a 32mm (diameter) and 500 mm long tube and cut in three pieces. These tubes will be used for our prototype.

The difference with the one we have produced before is that this tube is clear so we can see inside of the tube. Using this clear PVC tube would be much better than using glass tube as it is strong and not breakable.

Friday, August 31, 2012

Wednesday, August 29, 2012

Prototype A

Powder Dispenser (Prototype A)

We have done the

test to find out the volume of the 403 powder we needed for specific

consistencies as shown below in the table, which are the amount of powders we need

for a certain job when we are building a boat.

West system

403

|

Weight (g)

|

Density (g/ml)

|

Volume (ml)

|

Ketchup

|

3

|

0.111 g/ml

|

27.027 ml

|

Mayonnaise

|

5

|

0.111 g/ml

|

45.045 ml

|

Peanut Butter

|

11

|

0.111 g/ml

|

99.099 ml

|

From the test, we have measured the weight of the powders and then

calculated the volume of each consistency Ketchup, Mayonnaise and Peanut

Butter. The next step was to produce the tubes for each consistency with the

right size by the volume. We have found some materials from our workshop which

were the PVC tube as shown the photo right.

From the test, we have measured the weight of the powders and then

calculated the volume of each consistency Ketchup, Mayonnaise and Peanut

Butter. The next step was to produce the tubes for each consistency with the

right size by the volume. We have found some materials from our workshop which

were the PVC tube as shown the photo right.

However, we are looking for tubes that we can see inside the tube. As shown

in the photo right, we have made the tool that we can dispense the powders

effectively. We need the tube something similar to the one showing in the

photos.

Therefore, we have researched the more tube that is more clear. The supplier and the price and other details will be shown below in the table.

Product

|

Supplier

|

Diameter (mm)

|

Quantity

|

Price ($)

|

PPVC/040

|

Plastic Systems

|

40

|

1 (m)

|

54.35

|

Tuesday, July 24, 2012

Concept sketch (3D modelling) and the next steps

Concept sketch (3D modelling)

The next steps -

- Type of materials

- Operating systems

- Size of the device

- Method of minimising the powder dust

- Cost

What is better than existing solutions?

More details

The next steps -

- Type of materials

- Operating systems

- Size of the device

- Method of minimising the powder dust

- Cost

What is better than existing solutions?

More details

Saturday, May 19, 2012

Definition of the problems to be solved in relation to the project

These pictures above show how the powders are stored in the workshop. Generally people do not concern much about the health hazards when they are handling the chemicals. Affect can be different depending on the exposure, but it may cause measurable changes in the body, such as decreased pulmonary (lung) function which can be a serious medical condition to have.

2nd problem - Incorrect mixing ratio and wasting of materials.

The picture above shows the typical material lose when we mix the powders and resins. There are allocated ratio of mixing for different jobs however at the moment the correct way of mixing these are only differentiated by its texture.

Therefore once we have mixed them in a incorrect ratio there is no choice but to discard them completely.

If we can mix them and have same correct result every single time it can lead to no waste, cost efficient jobs.

Wednesday, May 9, 2012

Choosing powders for the project

The above image is filler selection guide which is provided by West system.

When I was considering about choosing a powder or powders for our project that I thought if we choose the powder types which are mainly used for building construction at the work shop that would be better choice than non-related powder types. Therefore I found two types 403, 410 filler powders which are mainly used for 5.5 Robshaw racing building process at the work shop.

403 filler was largely used in various way such as general bonding and laminating for the building process and particularly 410 filler is used for surface fairing.

These two powders have different densities, so finding a right ratio will be a big issue to achieve our project's goals.

Tuesday, May 8, 2012

Filler powder equipment manufacturer: Shanghai Dahe packing Machinery CO., LTD

This machinery is designed for the powder which easily to spout dust such as filling addictive, carbon powder and other fine powders. The machine has a weight sensor so it can do measuring. The weight sensor can control the speed, and hence it can pre-set the weight and the choose the options from either fast filling or slow filling. The description below shows the process of filling and measuring powder.

Process

Process

1. Put bag/can(container) on the machine

2. Container raise

3. Fast filling

4. Container declines

5. Weight reaches the pre-set number

6. Slow filling

7. Weight reaches the goal number

8. Take the container away manually

Model

|

DCS-5B-1

|

DCS-5B-2

|

Packing Weight

| ||

Packing Accuracy

|

100

|

1 –

|

Packing Speed

|

5 - 30 times per min

|

2 - 25 time per min

|

Power Supply

|

3P AC208 - 415V 50/60Hz

|

3P AC208 - 415V 50/60Hz

|

Total Power

|

2.7 Kw

|

3.2 Kw

|

Total Weight

| ||

Overall Dimension

|

1030×850×

|

1130×950×

|

Hopper Volume

|

The table above shows the comparison between two different power machineries which includes some key point that are the weight and the speed.

http://www.dahepack.com/en/showproduct.asp?cid=91

Friday, April 27, 2012

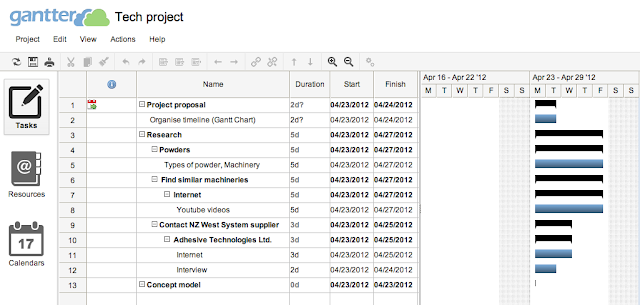

Gantt Chart

The image above shows the process for the project, and it gives the timeline with the start and the finish date for each stage.

This software is called "Gantter" that it allows us to work collaboratively online. In addition, we can work with using MS project and the file can be imported to Gantter.

Saturday, April 21, 2012

Filler powder equipment manufacturer: EV Global

Our machinery will be designed to measure and dispense a designated

amount of powder into a container. A specially sized cup will be used to

measure the proper amount of powder to fill into a container.

This

website shows various types of powder machine. Most of the machines are expensive, and the most expensive one is about $35000.

The image on the right is one of the filler powder machines manufactured by EV Global.

I think internet is also a very good research tool for us to develop our thinking and design our product.

Friday, April 20, 2012

West System NZ supplier

West System NZ supplier

Adhesive Technologies Ltd.

17 Corbans Ave., PO Box 21169

Henderson, Auckland 8, New Zealand

Tel - +64 (9) 838-6961

Email - grant@adhesivetechnologies.co.nz

Here is contact of west system NZ supplier above.

They are located at Henderson and we are going to interview them to gather more specific information about each powder's properties. Thus it will be a good opportunity if we get their advise and suggestions to be adapted them into the project as well. Therefore we can choose appropriate powders for our machinery.

Sunday, April 15, 2012

Project Proposal

Title

A development of innovative machinery that measures the correct amount of powder ingredients used in marine industry.

Problems

Incorrect amount of powder ingredients in wrong ratio with resin causes different results when it is mixed together. Also powder ingredients left in open area can cause bad influence to work environments as the chemical dusts spread out.

Objectives

The purpose of producing this machinery is to measure the correct amount of powder in order to minimize the waste. Also since the powder ingredients are stored in our custom secured system, the amount of dust will be eliminated and the work environment will be tidy and clean. The device will be set the standard which provides consistent ratio of powder when using with resin. Consequently, it can provide the same results to designers and builders who are using the device.

Goals

1. To design and produce a machinery which provides the necessary amounts of powder for a variety of situations

2. To produce a machinery that can reduces dust out of excessive powder in order to provide better work environment

Key Activities

1. Break down all project work into several activities such as creating a timelines using the project management software

2. Survey and discuss the various possibilities with the experts and industry representatives.

2. Survey and discuss the various possibilities with the experts and industry representatives.

3. Research the existing products and apply the technology into the system

4. Design the concepts for the project on the basis of the research

5. Produce the prototype of the project

Expected Results

The machinery will provide a standard way of managing the amount of powder especially for people who do not have much experiences or knowledge of handling the materials.

Subscribe to:

Comments (Atom)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)