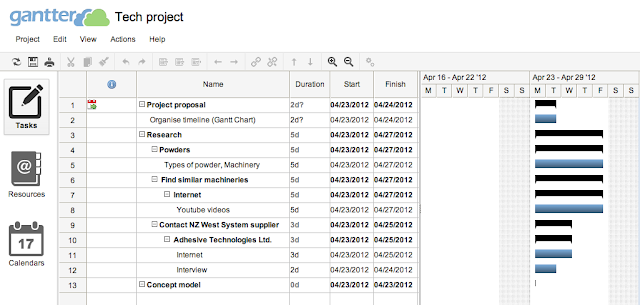

The image above shows the process for the project, and it gives the timeline with the start and the finish date for each stage.

This software is called "Gantter" that it allows us to work collaboratively online. In addition, we can work with using MS project and the file can be imported to Gantter.